| Sign In | Join Free | My portofva.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My portofva.com |

|

Brand Name : XWH

Model Number : D(N)B--100,D(N)B--160, D(N)B--200, D(N)B--250

Certification : CE, RoHs

Place of Origin : China

MOQ : 1

Price : USD2500-USD4000

Payment Terms : L/C,D/A,D/P,T/T,Western Union,MoneyGram

Supply Ability : 50 sets/month

Delivery Time : 30 working days

Packaging Details : Wooden Case

Product name : Screw M12X1.5 Nut Bowl Feeder

Application : Automatic Feeder Machine

Usage : Brass Square Nut Bowl Feeder Machine

Machine type : Automatic Feeding

Keyword : Automatic Screw Feeder Machine

Color : Customized

Feature : Weld Nut Feeder Machine

Warranty : 12 months Guarantee

After Warranty Service : Video technical support, Online support and Spare parts

After-sales Service Provided : Free spare parts, Field installation, commissioning and training

M3 M6 M8 Steel Rivet Flange Nuts And Bolts T Nuts Bolt And Nut Vibratory Feeder

Product Introduction:

Nut conveyor is a key auxiliary equipment in modern industrial automation production lines. As an intelligent "material distribution unit", it seamlessly integrates with robotic arms, PLC main controllers, visual systems, and locking actuators (such as electric batch and servo tightening shafts) to form a complete automated assembly workstation. Its professional value lies in achieving precise synchronization between nut supply and the entire production cycle, which is an indispensable foundation for flexible manufacturing systems and intelligent factories.

Features:

1. High speed conveying capacity: Using compressed air as the power core, the nut is instantly blown to the designated position through a precisely designed conveying pipeline, and the entire process is completed in milliseconds. It is particularly suitable for assembly lines with extremely high production pace requirements and can significantly improve overall assembly efficiency.

2. Simplified system structure: mainly composed of vibration disk sorting unit and high-pressure blowing unit, with fewer mechanical moving parts. This concise design brings higher reliability and lower failure rates, and daily maintenance work is relatively simple, usually only requiring ensuring a clean gas source and smooth track.

3. Excellent cost-effectiveness: This type of solution is one of the lowest initial investment and long-term maintenance costs in achieving automated conveying functionality. It provides an ideal entry point for many businesses with limited budgets or those seeking quick automation returns, with a short investment payback period.

4. Flexible installation adaptability: The conveying pipeline can be flexibly laid out according to the spatial layout of on-site equipment and workstations, and can bypass some obstacles to deliver nuts to narrow or special angle positions that are not easily accessible by robotic arms.

Technical Parameters:

| Power Supply | AC220V, 50Hz / 60Hz; Max 250 - 400VA |

| Nut Shapes | Square, round. Hexagon, T, dome, with cover, with rib, collar etc. |

| Air Pressure | 0.25 - 0.4MPa |

| Sizes | M4 - M12, 7/16 |

| Bowl Size | φ260mm, φ350mm |

| Hopper Capacity | 9L (10,000 pcs for M6 nut) |

| Supply Capacity | 40 - 60pcs/min |

| Supply Chute Length | 2m |

| Angle | 0° - 90° |

| Weight | 50kg |

General Structures:

Detailed Images:

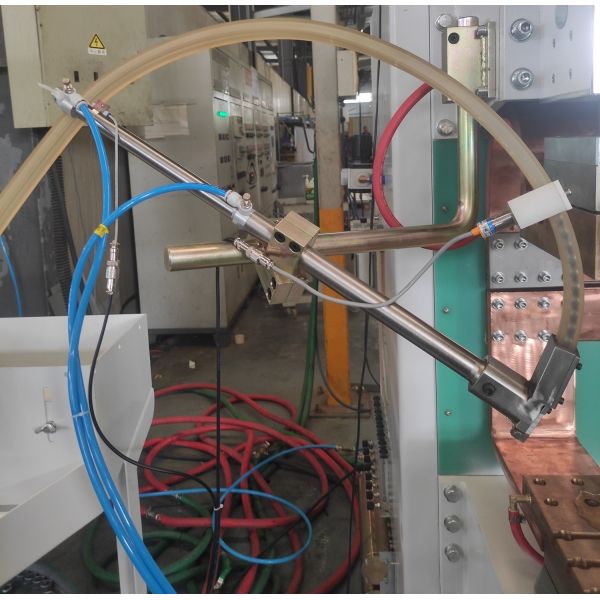

Scene Images:

Application:

Supporting Point Projection Welding Machines:

FAQ:

|

|

M3 M6 M8 Steel Rivet Flange Nuts And Bolts T Nuts Bolt And Nut Vibratory Feeder Images |